Bucket of slop - or pot of gold?

Non-conformance Reports (NCRs) are varied – they can be anything from rework to complaints; failures to recalls. They can also be identified by a number of different groups – external customers, auditors, testers or staff in other departments.

While NCRs may be a diverse lot, what they do have in common is their immense power. NCRs can be the little gold nuggets that keep your organisation nimble, improving and growing with a healthy bottom-line. Or… they can be toxic little gumballs of lost profit, interdepartmental fighting and missed opportunity. It’s all in the way you treat them.

I was talking to a colleague the other day about NCRs and he relayed an old story that really resonated with me. Let me share it with you.

A Story about NCRs from the Quality Department

Back in the early 1990s my colleague’s first quality-based role was as a Quality Coordinator at a packaging company. For this company it seemed the MO was to throw as much paper at NCRs as possible. Every NCR required an extravagant six copies – one each for the extrusion department, accounts, sales, print, converting and, of course, the Quality department.

Keeping track of all the copies was like rounding up chickens – he had to keep spreadsheet registers detailing where each copy was and much of his working day was spent following up with each department to ensure that the copy was being managed.

This paper deluge resulted in taking an average of seven weeks to process a credit!

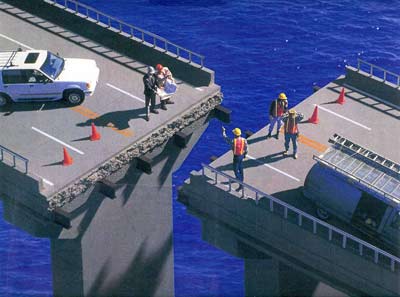

And because of outstanding credits, customers were not paying invoices. Unhappy customers meant an unhappy sales department.

Knock-on effect: the sales department was at loggerheads with the accounts department.

Further negative effect: customer services were continually putting out fires.

It never got to the point of outright war at the annual Christmas party – they were a good bunch of people who rose above the many, many NCR frustrations – but it was a close-run thing.

Oh, and the value of NCRs was a massive 7% of turnover!

It was clear something needed to be done and so my colleagues set about re-engineering the whole process. Here’s what he did:

- He created a new NCR form with only ONE duplicate copy.

- The department responsible for the corrective action was given the form.

- The copy of the form was given to the Quality department for tracking purposes.

- He implemented a weekly NCR meeting to discuss each issue and make sure that each corrective action was being dealt with.

- For the payment of credits he set a target of 7 days for the accounts department.

The process was now simple and clean, and sure enough, things quickly improved. NCRs were more visible, and departments took responsibility for the corrective actions and were accountable if issues were not dealt with on time.

Increased visibility of issues also meant that trends were much more easily identified – and thus preventive actions were more readily implemented. Departments were better able to focus and so made better decisions. Credits were paid on time, which meant that invoices were paid on time.

Now, the Quality geek in me loved the simplicity of the new system, but what I loved most was this: the value of NCRs quickly dropped to 0.7% of turnover – a ten-fold improvement!

The Takeaway

You need to treat NCRs for what they are – organisational GOLD. They are feedback, a cause for pause, a chance to look at not just the detail of what you do, but also the big picture. But deal with NCRs sloppily and they have the power to put departments at loggerheads, get customers bad-mouthing you and reduce your profits.

In a nutshell, here is what you need to do:

- Make the NCR process visible to all staff.

- Keep the process simple (if it’s simple, it’s more likely to be used).

- Allow for collaboration across departments. Talking is good.

- Hold people responsible for corrective actions and accountable for their outcomes.

- Set some simple targets - and achieve them.

Take the time to look carefully at your NCR process. Sure, it will take some effort to optimise the process but it will pay off big-time.

Keen to know more about how Mango helps organisations improve their NCR process practices?

.png?width=200&height=51&name=image%20(2).png)